Hot-Selling Defeathering Poultry - Weight Grading Machine-Sweep Arm – JIUHUA

Hot-Selling Defeathering Poultry - Weight Grading Machine-Sweep Arm – JIUHUA Detail:

Functional characteristics of the equipment

1. Imported special dynamic weighing module is used to realize high-speed and stable measurement.

2. 7 inch or 10 inch color touch screen interface, simple operation;

3. Fully automatic selection method to avoid human errors human power;

4. Automatic zero analysis and tracking system to ensure the stability of detection;

5. Built-in temperature and noise compensation system to ensure reliable data;

6. Powerful data statistics function, recording daily detection data, can store 100 sets of product data, convenient for customers to call, and sudden power failure data will not be lost;

7. Frequency conversion speed regulation mode is adopted in the conveying system to facilitate the speed coordination between front and rear.

8. Dynamic weight compensation technology, more real and effective detection data:

9. Self-fault diagnosis and prompting function to facilitate maintenance;

10. Imported stainless steel SUS304 rack, in line with GMP and HACCP specifications;

11. Simple mechanical structure, quick disassembly, easy for cleaning and maintenance;

12. Sorting method: Automatic Sweep Arm;

13. Data external communication interface can connect other devices in the production line (such as marking machine, jet printer, etc.) and peripheral USB interface can easily realize data export and upload.

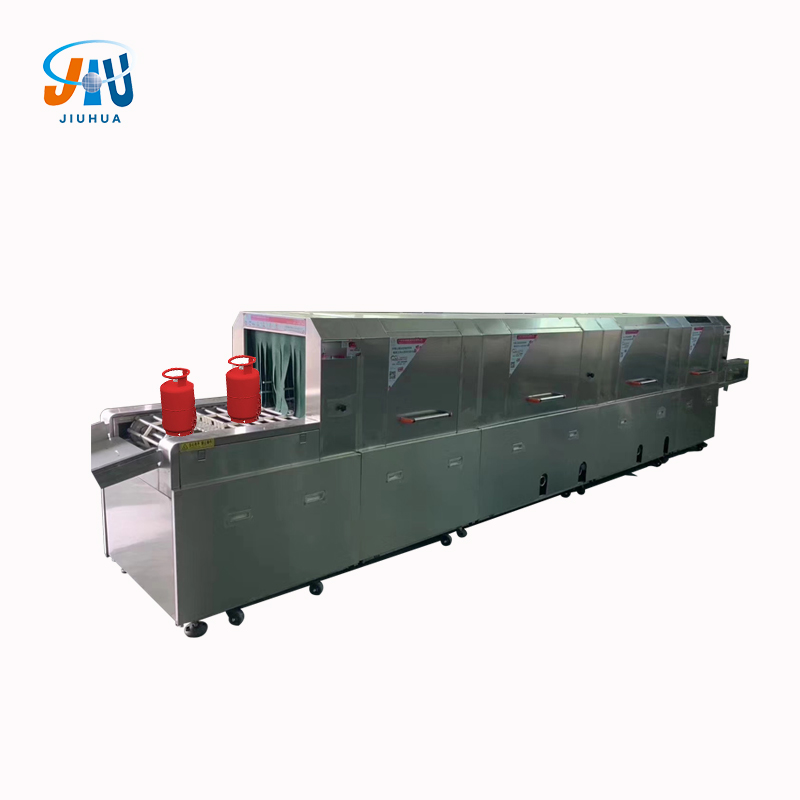

Product detail pictures:

Related Product Guide:

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for Hot-Selling Defeathering Poultry - Weight Grading Machine-Sweep Arm – JIUHUA , The product will supply to all over the world, such as: Birmingham, Sweden, Belgium, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.